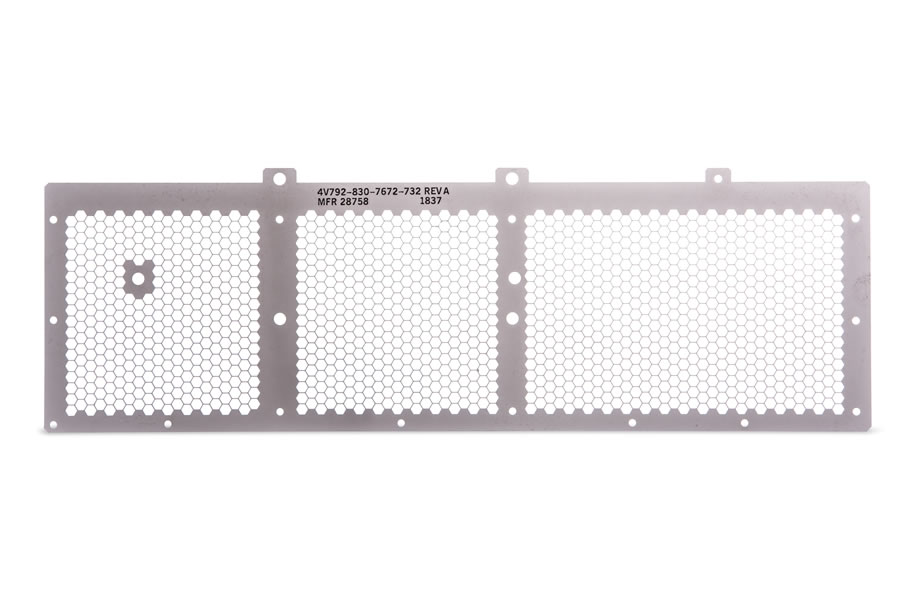

ADVANTAGES OF CHEMICAL ETCHING

- SUPERIOR FOR PROTOTYPES: Excellent precision, repeatability, and accuracy, quick turnaround. Engineering changes and modifications can be made quickly, easily, and inexpensively.

- LOW COST: Compared to hard tooled parts, the chem-etch photo tool is more efficient and far less expensive than typical hard tooling. Unlike hard tooling, complexity of a part is not a cost driver.

- NO HARD TOOLING: no major investments, no die maintenance and repair costs, no long tooling delivery delay. Photo tool lead time is normally 1-2 weeks and can be shortened if necessary. Photo tool charges are substantially lower than conventional die shop charges.

- NO METAL STRESS OR PART DEFORMATION: Chem-etched parts remain flat since the metal removal is achieved chemically, not mechanically.

- BURR FREE: Secondary deburring operations are eliminated since no metal to metal contact stress occurs.

- MATERIAL PROPERTIES: Remain unchanged. Temper of metal is not changed. Magnetic property is not affected.